MKS HBL665/669 High-Voltage Servos

Written by: Justin Pucci

First off, I want to give a big thanks to Thomas Cooke of MKS USA for giving me the opportunity to review these great servos. As you all know, the servo market is a tough little sector of our beloved hobby. There are a bunch different brands that claim to have the best servos out there, but many of them don’t live up to those claims. I’m not here to convince you that your favorite brand of servos isn’t up to snuff when compared to MKS, but I’m definitely going to tell you about the very positive experience that I’ve had with these servos and why I think that you should give them a look before you rush out to buy your go-to brand for your next build…

Product Description

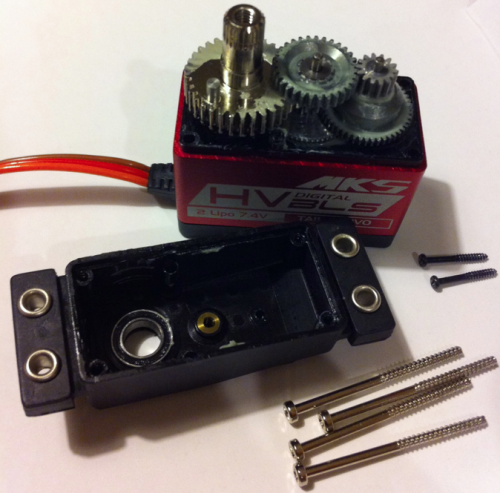

I was fortunate enough to get ahold of one of MKS’s HBL servo holiday package deals before they sold out last year. This package comes with three of the HBL665 cyclic servos and an HBL669 tail servo mounted in a nice little display and includes servo horns, mounting hardware, some gear grease, and a really nice silver MKS sticker! Very nice touch, guys… As you all know by now, I’m very picky about how products are marketed and presented to the consumer and it’s very important to make a good first impression. Well, MKS knocked it out of the park with this one for sure. Now, if you happen to have missed this holiday package deal, don’t fret…you can get these servos individually from you favorite MKS dealer or directly from MKS USA if you’re in the states.

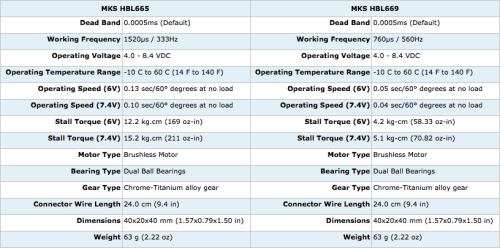

From the moment that you get one of these servos in your hands, you get a definite feel of quality. They are made up of a red-anodized aluminum main case with plastic upper and lower case covers and a nine inch servo lead. The specifications on these guys are quite impressive too. Take a look at the tables below:

As you can see, we’re talking serious business here…these ain’t your momma’s servos! 🙂 With a whopping 211 oz-in of torque at 7.4V, the HBL665 cyclic servos will take anything that you can throw at them and more and the HBL669 tail servo boasts 70 oz-in of torque with a blazing speed of 0.04 seconds at 7.4V! They both make use of a brushless motor with dual ball bearings, and a full chrome-titanium gear train and still only weigh in at 63 grams, which is a big thing for me. The lighter the better…

Bench Testing

Alright, you guys know me, right? How can I do anything without being nerdy about it?! That’s just what I do, so why stop now? As an engineer, I’m a data-driven kind of guy, so rumors, anecdotal evidence, and the like have no place in my research and decision-making process when it comes to selecting products to put on my helis. I wanted to do some bench testing of the MKS servos against some servos with which I’ve got prior and extensive experience. I mean without data to back up my claims, how is this any different than the other opinions floating around out there?

One of the most important features of a servo to me is their efficiency. Why? Well, when a electrical system is efficient, it runs at cooler temperatures and an altogether lower stress level, which translates to longer life and more consistent performance over life. Remember that we’re dealing with electronics here and what that means is that temperature is our enemy. As the temperature of an electronic system increases, so does its resistance, which causes higher power dissipation (less efficiency) and, in turn, leads to higher temperature and the whole vicious cycle continues… This is call a positive feedback loop and it’s something that we want to avoid at all costs.

It’s not only important to make sure that the servos run cool, but that once they’re hot, they cool down as quickly as possible. To this end, I devised a little bench test that allowed me to compare the thermal performance of the MKS servos against a Hyperion DS20x-SCD high-voltage cyclic servo and an Align DS610 cyclic servo at 8.4V. Here’s what I did:

1. Plug the servo into a Spektrum 6115e DSMX receiver linked to a DX7 radio.

2. Power the RX with a Castle Creations BEC Pro at 8.5V.

3. Measure the idle-powered servo temperature once per minute for five minutes.

4. Actuate the servo through full throw at a frequency of 1Hz (1 cycle per second) for five minutes while measuring the temperature every minute.

5. Let the servo cool off in the idle-powered condition while measuring temperature every minute for five additional minutes.

Not too bad, right? Before we get on to the data, let’s talk about the three main phases of the test and what they’re objectives are… In phase 1, the servo is in the idle-powered condition. This gives us a feel for how efficient the unit is when not loaded based on how warm it gets after five minutes. Phase 2 puts the servo through a five-minute active period of continuous, 1-Hz, full throw translations and this tells us how efficient the unit is when subject to a dynamic condition. Finally, phase 3 checks how rapidly the servo cools back down from its hot temperature, which is an indication of the heat sinking design.

So, what did we learn? Well, the MKS servos turned out to be the coolest running of the three servos tested. During phase 1, all three servos were pretty much on par with each other in terms of idle-powered warm-up. In fact, they only varied by around two to three degrees over the five-minute test period. Once phase 2 began though, the differences started to become more apparent. You can see from the plot that the Hyperion and Align servos heated up much more rapidly than the MKS did and as a result, they were four and seven degrees Fahrenheit hotter than the MKS, respectively at the end of phase 2. The three servos seemed too cool down at approximately the same rate during phase 3, but since the MKS started at a lower maximum temperature, it also reached a much cooler temperature after five minutes of idling. So far, so good… How do they perform on a heli though?

Installation and Flight Performance

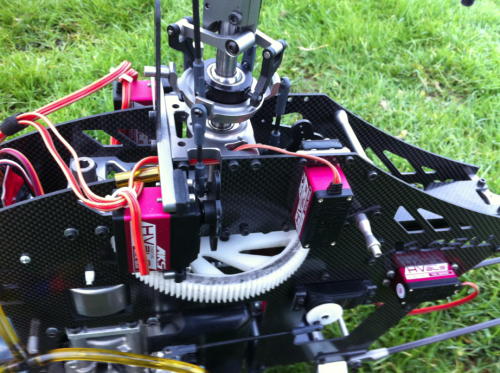

Before we get started on this part, let’s get the test rig out of the way… I decided to test these servos on my Miniature Aircraft Whiplash Gasser, since I would be breaking in a brand-new engine and wanted to see how they faired against the constant punishment that is fuel engine break-in and tuning. The heli was running a direct 2S lipo receiver pack, Revolution 710 FBL blades, KBDD Extreme 112mm tail blades, a TRM 270 Turbo engine, ADARacing pipe, and Coleman fuel at head speeds between 1800 and 2100 RPM. All of this testing was performed in winter weather ranging from 19F to 45F and almost always 100% humidity.

The first thing that I noticed when I installed these servos and got them all linked up to the head and tail was that they have absolutely zero slop or play! They have the tightest gear trains that I’ve ever witnessed and it showed not only by manipulating them by hand, but also by watching how they “settled” when blades were added to the head. No sinking, no deflection, nothing…just rock-solid. When powered, they’re also very quite. I know…not a big deal to most, but I hate listening to digital servos squawk away at me while doing setup or programming. The servo arms are beefy and the splines line up perfectly. I was able to get all four servo arms installed at a near-perfect 90 degrees with no need for sub-trimming.

I then began the grueling and patience-trying process of breaking in the gasser. This took me quite some time, as the break-in requires a minimum of one gallon of fuel with a petroleum-based oil in it before transitioning to a synthetic oil and after each flight, you need to let the engine completely cool back down to ambient temperature to heat-cycle it…This all translates to a long break-in time, especially when you throw our awesome Pacific Northwest winter weather into the mix.

When you’re breaking one of these things in, you’ve got to keep the mixture rich and that means loads of vibrations. In all, I’ve put a total of two gallons (over 20 flights) through this heli with the MKS servos on it as of the time of this review. Now, I know that you’re saying to yourself “20 flights?! That’s nothing…” Oh, but you forgot that each flight is 10 to 12 minutes long because it’s a gasser! So, in just 20 flights, I’ve put over four hours of flight time on these servos, which is roughly equivalent to over 50 five- to six-minute flights on an electric heli. After all of this, the servos are still just as tight as they were when I pulled them out of the box. They still center amazingly well and run quietly too.

During regular flight, the cyclic servos feel very connected and responsive owing to their lash-free metal gear trains and high torque. They don’t have that mushy and delayed-reaction feel of a lower-torque servo or plastic gear train that some of you may be familiar with. Furthermore, the tail servo is lighting-fast and extremely precise during pirouetting stops and direction changes. The deadband on these things is almost non-existent too. You get an immediate jump to action coming off center stick and there’s no sloppy feeling when doing precise flying around center stick either.

What about the efficiency? Over the 20 flights that I put on the servos, I measured an average draw of 200mAh per flight. That’s around 17mAh per minute! I’ve never experienced a more efficient servo system in my life. Wow! It just keeps getting better…

And what kind of product testing would this be if it didn’t include a crash test? 🙂 Yes, I sacrificed my beautiful heli in order to better inform you all. During break-in, the foggy and dark Pacific Northwest weather caused me to momentarily lose orientation, as I was flying without a canopy. The result was driving it in to a patch of mud pretty hard. I was quite concerned about the servos at first, but much to my surprise, they were completely intact. No broken or stripped servo horns, no case damage, no gear damage… Awesome!

Conclusion

Nowadays, there are tons of servos to choose from and most of them are on par with each other in terms of specs on paper, but not necessarily in terms of quality and longevity. I’ve flown almost all of the brands of servos out there: Futaba, Savox, Align, JR, Hyperion, and Hitec and I must say that these MKS’s are among the best experience I’ve had with any of brand. They’re very efficient for high-voltage servos and they’re sexy too!

Everything has negatives to it though, right? Well, honestly the only thing I could come up with in terms of cons is the price. First look at it from my perspective… Ever since I found Hyperion servos at a mere $50 each, I thought I would never buy another servo brand again. Now, for those of you who have flown them, the Hyperions leave a bit to be expected in terms of durability and performance, but they’re flyable and it’s easy to justify those cons when you’re not paying an arm and a leg.

So, when I first saw that the MKS’s were priced at $129.95 for the HBL665 cyclics and $133.95 for the HBL669 tail, I was a bit apprehensive. They’re actually cheaper than some of their high-quality competitors, but it still costs a pretty penny to fully equip a heli with them. That having been said, after flying them, I can definitely say that the quality and performance that you get for your money is amazing and easily exceeds the price of the servos! The other obvious con that follows from this is that I love these things so much that I’m going to have buy a bunch more to equip my other helis! Ouch! 😉

Again, I’d like to thank Thomas Cooke of MKS USA for giving us here at the Nation the opportunity to test the MKS HBL665 and HBL669 servos and as always, thank you to the listeners for your continued support and interest in our product reviews.

– Justin