Blade 700X Pro Series Combo Kit

Written by Nick Lenn

Well I can’t believe it but they’ve taken the plunge! Yes, Blade helicopters has taken the leap from the micro and smaller helis and finally put out a 700 class heli. They came out swinging with claims of not only a great design but competitive quality as well. Could it be? Can the same company that has dominated the micro market really make a competitive 700 class electric? Luckily, we were fortunate enough to have Blade send us the full 700X Pro Series Combo kit to run through the ringer and see if it held up to all the claims. I’d like to make a special point to say thank you to Steven Petrotto and Kim Payne from Horizon Hobby for putting this all together and helping make it happen. Also a huge thanks to HH team pilot Edsel Labao for awesome technical support through the process. I know I speak for all of our listeners here at RC Heli Nation when I say thanks for giving us the opportunity to do this review.

Well enough with the chit chat. Let’s get to building! Out of the box everything was packaged sufficiently and organized well. They definitely didn’t go too fancy on the packaging which I’m actually a fan of . It’s simple, effective, and all the of parts bags and components were adequately labeled and organized.

Here you can see everything that is included in the combo kit:

- Blade 700X Airframe

- Revolution 690mm FBL Main Blades

- Revolution 115mm Tail Blades

- Blade holder

- AR7200BX FBL System/Receiver

- Spektrum DSMX Satellite

- 3 x Spektrum H6200 Cyclic Servos

- 1 x Spektrum H6210 Tail Servo

- 3 x Spektrum wire pigtails for the servos

- E-flite 700 Heli 520kv motor

- Manual

The only thing I added to combo kit was a CC 160HV ESC, a CC BEC Pro, and a set of Gens Ace 6s 35C 4400mah batteries. Once I got everything sorted out I started taking a closer look at each of the components included.

The graphics on the Revolution main and tail blades look fantastic. They definitely picked a great pattern that should show up well in the air. The finish on the E-flite 700 Heli motor is surprisingly nice and overall the quality looked great. We had talked about the new Spektrum servos that have the plug-in servos wires awhile back on the show so I was really excited to see that they were included in this combo kit. The servos wires made a firm “click” when installed and despite my best effort of wiggling and prying I could not simulate them being pulled out without being properly released. The servo cables are also tightly covered with a protective sheeting which looks to give some great protection against chaffing and accidental nicks and cuts. I took the time to look up the specs on the servos and was blown away at what I found. The H6200’s are running at a speed of .06 at 8v and the H6210 is at an astonishing .03 at 8v. Wow! These things are no joke! I’ve got high hopes for these servos and hope they can provide really long life cycles. Despite having a lot of previous experience with BeastX this was my first personal encounter with installation of an AR7200BX and I have to admit it is a really nice and cleanly done little unit.

The canopy looked great in person! The colors are some of the best looking combinations I’ve seen. The second I took it out of the package I knew I was going to like it in the air. The quality was acceptable and I really like how it wraps back around in the back. Sometimes this feature can make for a canopy that’s a big tougher to put on but we’ll see how that turns out in the long run. I also really like that they included a blade holder in the kit. Nothing is worse than dropping your hard earned money on a 700 class kit and being stuck trying to track down a blade holder that matches the look of it.

I started with the rotor head as per the order that the manual suggested. I’d be lying if I wasn’t honest and admit that I wasn’t expecting a lot as far as finish goes with this kit. Blade has rooted from the micro heli world and established a certain quality that anyone who has owned a micro has come to expect from them. I don’t particularly think that it’s 100% unfair to feel that way despite being pretty stereotypical and would be willing to bet that a lot of people share those expectations with me. I was very shocked when I got the rotor head out of the package and started putting all the pieces together. This is NOT in any way shape or form the Blade that I knew! They really stepped up their game on the quality and finish that’s for sure. I was really pleased to see a standard style rotor head with swash follower arms and not a DFC style head. I feel this style of head flies the best and performs well through the widest range of head speeds. I did notice they chose to use a 4mm spindle bolt instead of the standard 5mm but even during install this really didn’t set of any alarms for me. I was really pleased to hear Justin’s results after running the numbers in episode #104 that even further squashes this being an issue. I found one small spot on the head block where they machined in just a tad too far and exposed some threads for the swash follower arms (100% purely cosmetic) but past that the head looks superb! The plastic links are great. They’re very robust and provide a nice firm “snap” when pushed on the balls. The swash plate yielded zero slop and the follower arms are definitely beefy enough to get the job done. I did notice a very slight amount of slop in the pins on the follower arms. I’ve also seen this in other brands that use the pin-style design. It’s not a big concern but with the amount of thought they put into the servo layout (which I’ll get to later) to get a heli that flies and tracks as precise as possible I’d like to see this slop removed int he future so it doesn’t case any phasing issues. It’s minimal now but I will monitor it over the long run. Another thing I really like is the double Jesus bolt design they incorporated in the head block. This is a really neat feature that prevents you from sheering the head bolt in a crash and having it spin around and destroy the inside of the head block. Overall the head is very well done. It’s not the fanciest thing or the most ground breaking but I can really appreciate the simplicity and quality implementation which I really think fits the overall theme of the kit.

After I got the head assembled I moved on to the main frame section. I gave the frames a quick sanding job like I always do, laid everything out, and began following the manual. This was where my first small little red flag went off. The order in which the manual has you assemble main frame components was rather odd. I cheated and looked ahead in the manual and confirmed that this was not the most efficient assembly process. I found a couple pictures and steps that didn’t show the components properly and the overall flow of the manual was not very good. There was certainly enough overall information and pictures in there to get everything assembled correctly the first time for myself but to be fair I do have a decent amount of build experience and I can see the potential for someone new to the 700 class market missing something during the build process and having to go back in when it’s all done because they’ve got a small piece left on the bench. My advice is to completely read through the manual before you start the build and make sure you’re comfortable with where all of the smaller pieces and shims go. If you do that you shouldn’t have any problems. This is a great instance of where a little common sense can go a long ways.

The overall frame layout is very simple and efficient. Again, nothing crazy or ground breaking but that’s one of the things I really like about this heli. They kept it simple, easy to work on, and effective. At first I wasn’t sure if I’d like the pinion support bearing assembly being attached to the motor mount but after getting it all setup and adjusting the mesh I really like it. It’s very easy to adjust the main gear mesh when it’s like this. The ESC tray provides adequate space for any size ESC and made for very short and clean battery wiring. No need for cap-packs or worrying about battery ripple with long wires. They give you two gyro trays to choose from so I opted to mount the CCBEC on the front tray and keep it close to the ESC. Again, all the pieces were of superb quality and fit together like a glove.

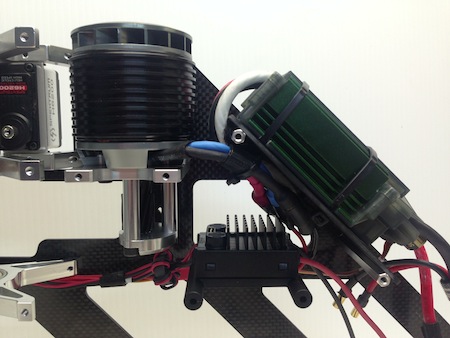

Here’s a close up shot of the E-flite Heli 700 motor. I was really impressed with the quality of the motor. It spins very smoothly and while the color might not be the fanciest in the market it really is a great motor overall.

Every single thing about the servo layout on this heli I have completely fallen in love with. They really did put a lot of time into the design on it while at first glance it might look like your standard direct-to-swash layout there’s a lot more to it. The way they have it setup with the servo output shafts on the inside and the arms arcing outward and away from the main shaft matches the way in which the swash plate moves. This yields very little negative mechanical interactions and provides the FBL system with one of the most mechanically ideal setups I’ve seen. They also made the servo mounting holes M3. I really like this because it allows you to ditch the rubber mounting grommets on the servos and just bolt the servos directly on without them sliding up and down. There’s no reason to be running the rubber grommets on an electric heli and it’s nice to see them recognize that.

Another insanely cool feature is they have also included the servo arms in the kit. They’re a captured-ball style that will not allow the link to come off in the event of a crash. First off, just including the servo arms in the kit is a major plus for me. It really is a huge pain to go through the dreaded forums and do the research to find out what servo arm is working the best for that specific heli. Sometimes specific arms don’t fit due to clearance, they offset the servo ball in the wrong direction, and the list goes on and on. I also think running a plastic servo arm is really important. I’ve completely exploded servo cases and destroyed countless gear sets using metal servo arms but often times you’re forced to run a metal arm because it’s the only one that will fit properly. Again, just one more reason why I love what they’ve done here. In the event of a crash you know you’re going to be able to purchase servo arms at the same place you’re buying your crash parts from. Love it!

You can see from the pic below how I decided to go about the order of install and change thing sup from how the manual suggested. I think this made the build process go a lot faster and smoother. I always prefer to do as much wiring as possible while I’ve got one frame side off. This picture also shows the overall simplicity of the model. In the last year helis have trended away from being fancy and overly complicated and I’m really glad to see the 700X following that.

I do want to note that I did not follow a small “suggestion” in the manual that I definitely should have. Once you have the frame sides on and the heli is all put together it is a bit of a hassle to get to the bolts that secure the servo horns to the servo. You’re way ahead of the game if you take the time to do the initial settings of the AR7200BX on the bench and just plug the servos in while they’re laying there. Get all the servo horns dialed in at 90* then go ahead and install them in the heli. You’ll save yourself some time later on. From here I decided to bolt on the right frame side, drop in the main shaft for proper frame alignment, then torque all the screws to button up the frames. It’s a little odd seeing the middle bearing block in there with no bearing in it. They chose to put a bearing in the top bearing block and lower bearing block and skip putting one in the middle one. This struck me as odd so I actually asked the Horizon guys about this. They said they thoroughly tested it in both configurations and found no benefit in having the center one in there. I see no reason to argue with that so I left it as it was.

When I first saw the battery latching mechanism was plastic I was a bit worried. That’s a lot of weight to be held in with a plastic latch. However, once I got to building it my worries went out the window. I’ll give Blade some major credit on this one. They’ve got some fantastic plastic here. It’s the perfect balance of strength and pliability. It’s not so soft you’re worried it’s going to come undone but it’s also not so brittle you have to worry about it cracking. Not to mention being plastic you get the advantage of keeping the weight down. I did add a little washer that wasn’t in the manual to each screw that secured the springs on the main mount to keep them from potentially popping off. After getting the batteries mounted to the tray and popping it in and out a couple times I really like this latching system. You get a nice affirmative “click” when they’re latched in and no worries that they’ll come out until you’re ready.

I love that feeling that you get when you pick up a part on a heli and it just makes you giggle because it’s so cool. Well the main gear fit the bill on this heli. This bad boy is 15mm thick! Combine that with a 13t pinion and you’ve got some fantastic tooth engagement. There are helis out there that you hear about people stripping main gears on and this is definitely NOT going to be that heli, lol. What makes this really cool is it gives me confidence that this airframe can handle even the biggest and baddest of motors in it. There’s nothing worse than upgrading your motor to the latest and greatest watt monster just to start chewing main gears left and right after that. You certainly won’t have to worry about that here. Another thing I’m really happy they thought about was the gear ratio. Stock configuration is 10.1:1. Combine that with the 520kv motor and it allows the heli to run very efficiently from 1900-2100rpm. I really don’t like a 700 class heli that’s designed to run 2100rpm and above and I have to say thanks to Blade for optimizing their heli for a range of head speeds that make the most sense. This also allows a nice variety of motor KV’s to work with this gearing.

The only downfall I found when I had the frame portion all buttoned up was that this heli will only fit a long/skinny style of battery pack. For instance, the normal Gens Ace 5300’s will not fit. The Gens Ace 4400’s, Pulse packs, Thunder Power, and any long/skinny pack will work just fine. At first this was a big of a turn off but then if you really think about it you’re not going to be swapping packs back and forth from heli to heli with a tray style configuration anyway so it’s really not a big deal.

Blade opted to go with their signature one piece landing gear on the 700X. It’s certainly not what I’m used to seeing and at first seemed a bit cheesy. Once again, however, I was proven wrong with function winning over looks. I have another heli that I’ve actually worn the plastic skids down enough to where the skid tubes are constantly turning. This would never be an issue with this style. Then when I priced out how much, or little should I say, these skids are I really had to re-think my position on them. So while the looks are still growing on me they get a huge win in function and cost.

Here you can see the AR7200BX mounted on the rear gyro tray that sits above the tail boom block. This picture also gives a good look at the sheathing on the Spektrum servo wires. After taking this picture I actually went back and carefully peeled back some of the sheathing to allow for a little less vibration transfer to the FBL system. Not a big deal at all and it was very easy to do. There’s not a ton of room to hide/mount wiring up around the gyro tray so removing some of that sheathing created a bit more room and allowed for cleaner wiring.

I then moved on to the tail assembly and immediately noticed how nice and clean the one piece tail box design was. No plates on the side with additional hardware to hold them on. Very clean and simple. I also really like how the actual gear is secured on the tail output shaft and the front tail transmission shaft. The gear slides on to the shaft then you insert a pin through it. Once the pin is installed you install a small set screw down through the center of the hollow shaft and tighten it down on the pin. This is a fantastic design that means you don’t have to buy both the shaft and the gear in the event of a crash. All of the tail drive system gears seemed adequately robust and well designed. One thing I did notice though was both the front and rear TT gears had too much backlash for my taste when installed as per the manual with the rear being the most prominent. After all the initial review flights I did go back and install a thin shim behind the TT gear before it was inserted in to help remove this. I want to be very clear that I had zero issues with the way it was in the stock configuration but I felt tightening up the gear mesh made for a much stronger mesh setup.

The tail shaft and tail grips are adequately sized and designed and provide a very smooth and slop free setup. One other point of controversy is the tail control arm. I made sure and stayed out of the forums before I got the review done to make sure and not sway any opinions I had but I have heard of people having issues with the tail control arm popping out of the slider. My initial impression when picking the piece up is that it is not as beefy as I’d like to see it. I don’t particularly think it needs to be aluminum but with the plastic molding abilities that Blade has and with how well designed and implemented other areas of the heli are I was a bit disappointed with this piece. I left it exactly as it was, installed it, and made the decision to fly it with an open mind and just be cautious at first.

They opted to go with a 23mm torque tube which I think is a great idea on their part. It puts a lot less fatigue over time on the boom itself and relieves a lot of stress on the boom supports and mounting points. The TT ends were a bit loose in the TT gears for my liking but not enough where I was worried about then stripping or anything like that.

Another cool little thing is since they designed this heli and tail gear ratio around a 115mm size tail blade it actually has a tail fin long enough to keep 115mm blades safe. Yay! Sounds simple enough, but it’s really annoying when you have to bump up to 115mm blades on a heli to get decent tail performance at lower head speeds and then end up chewing through tail blades when you land on an uneven surface or shoot autos. No issues with this heli!

With everything installed I ran through the setup on the AR7200BX in no time and looked everything over one last time. I’m not going to spend a bunch of time talking about the AR7200BX. It’s been out for quite a while now and pretty much everyone in the hobby is well aware that it is one of the simplest and best beginner/intermediate FBL systems out there. It provides superb out-of-the-box performance and is known for it’s high level of forgiveness on settings. It’s a fantastic system for Spektrum users and will get you up and enjoyably flying in no time.

About the only thing I noticed before flying that I wasn’t keen on was that because of the lack of front canopy mounts the canopy rattled a bit in the front. There’s definitely no concern for it coming off as it wraps well under the nose of the frame but it certainly wasn’t a snug fit in the front.

From there it was time to quit looking at it and get this bad boy in the air!

Maiden flight went exactly as I had hoped, uneventful! That sounds rather blah but in the heli world a uneventful maiden is a wonderful thing, lol. I did land it after a couple minutes and check it over for an odd noise I was hearing under load. Humorously, that noise turned out to be the Revolution blades. They’ve got a very unique sound to them that honestly I don’t care for. After I got the maiden out of the way and did my usual routine of rechecking everything over it was time to start tuning. Within 3 flights I had the governor gain dialed, cyclic tuned, and the tail good enough to start beating on. Wow! The flight performance of this heli absolutely blew me away! I couldn’t believe that a “Blade” heli could fly this good. All the worries about stereotypes went by the wayside and I proceeded to give this thing everything I had. It was so smooth and precise I was really shocked. The tracking is amazing. It’s almost like you can feel the time and effort they put into the servo layout and frame design in the air. It locked right in to maneuvers and just hung there like it knew what to do. The only thing I wasn’t just floored with right off the bat was the tail. Now I’ve put more than my share of flights on the BeastX FBL system and am well aware that the tail performance isn’t the best in the FBL world but it was still a bit off. After looking at my gains and rechecking everything I figured out that the tail servo horn is just too long. Stock configuration uses the same servo horn on the tail as the cyclic servos. This is too long IMHO and gives a too much mechanical gain. I couldn’t get my gyro gain up high enough for the tail to really lock-in properly. I picked up a set of JR splined servo horns and dropped it down to 14mm ball-to-center distance. That was the ticket! Tail performance climbed up dramatically and we were back to the beating! What a treat to fly this heli is. It’s so smooth and I’m still just amazed at how great of an all around performer it is. I think the head design and gearing really play well together because I settled on 1960rpm and about 13.5* of pitch and it was incredible. Very predictable and precise. Power delivery was smooth and the motor performance was unexpectedly awesome. The servos seem to be performing perfect and are playing quite well with the CC BEC Pro. Without question these best combo kit setup I’ve flown to date.

After about 30 flights in this configuration I only had two real complaints. I still didn’t like how the canopy rattled in the front. It just bugged me and mentally took away from how much I was enjoying the heli. I actually ended up adding another set of the stock canopy mounts to the front. Easy! Problem fixed. Last complaint was the blades. I think these are a decent set of “kit” blades and technically fly just fine but I simply didn’t like them. They sounded very inefficient and I think there was a lot more performance the heli had to offer that was being masked by the blades.

At that point I felt I had a really good feel for what the combo kit had to offer all around. As a lot of you know, I fly Futaba on a regular basis. Now while being in this position I do get to fly a lot of different equipment, and am generally quite comfortable flying just about anything, but there’s still something to be said about flying with your own radio. Because the AR7200BX is a Spektrum unit I decided to remove it and replace it with the FBL system I’m flying on my other day-to-day test helis. I’m the most familiar with how that particular unit flies and I felt between that, swapping to a brand of blade I’m more familiar with, and my own radio I could really get the most accurate depiction of the airframe possible.

Within two flights I was giving this heli everything my skills had to offer. No bobbles. No wobbles. Tuning was a breeze and very predictable. It simply took everything I had to give and just begged for more. The cyclic flow was great and piroflips flowed right along. As my comfort level increased I was shocked and how the motor kept up. Pulling 4900w continuously in a hurricane was a breeze and showed no signs of bogging. It might not quite have the power that some of the aftermarket power monster motors on the market today have but there is ZERO reason this motor won’t keep up with 95% of the pilots flying today and is just as good, if not better, than most of the stock motors out there. Tail performance was superb and while that tail control lever was still in the back of my mind I can honestly say that I never had a single issue with it.

Overall, I have to take my hat off to Blade and what they’ve created with the 700X. This heli has meet and exceeded my expectations all around. I’ll be very honest, there are a couple of small things that I would like to see them fix but once those are taken care of this heli really is playing with the big boys. They set out to create a simple and effective designed heli that performed fantastic and that they could produce at a cost that the average hobbyist can afford. With those goals in mind I think they couldn’t have nailed it any better for their first 700. Even the smaller quirks that I found I were able to fix (those fixes can be found in our tech-tip section btw) and that is really the biggest key. There are no major design flaws or implementations that will keep this heli from moving forward and being more and more successful. I think we can all take even the fanciest and the most popular helis on the market today and find a hand full of small things we don’t like about them so keep that in mind. Yes, I did pick this heli apart a bit but you know what they say… you pick on the ones you like 🙂 So guys and gals… I can officially say it’s time to ditch the whole, “Yeah but it’s a “Blade” heli” thing. This heli no joke and will stand toe to toe with the other 700 class helis on the market today. Combine that with the opportunity at local parts support and the superb customer service of Horizon Hobby and we’ve got one heck of a winner on our hands here.

Again, we here at RC Heli Nation would like to give a huge thank you to everyone at Horizon Hobby especially Steven Petrotto and Kim Payne for helping make this happen. Thanks to Horizon Hobby team pilot Edsel Labao for answering any questions I had and a huge congratulations to everyone on the design team for the Blade 700X. You did a fantastic job and have proven that Blade is a definite contender in the 700 electric class of helis. Great job!

– Nick Lenn