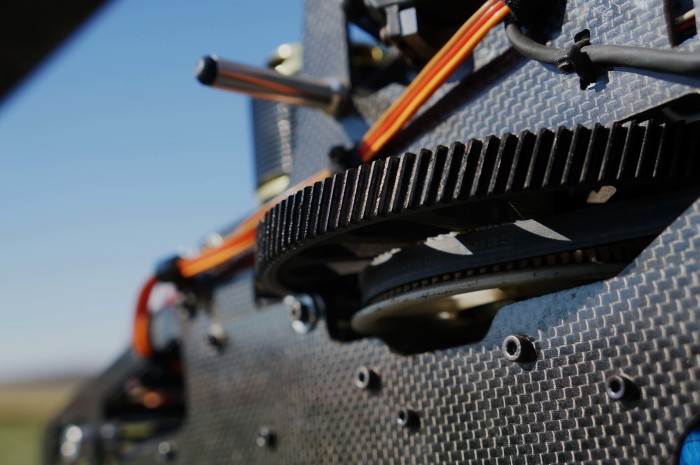

Getting that perfect gear mesh between the pinion and the main gear can be quite the challenge. However it is not something to overlook the importance of. As too tight of a gear mesh can lead to premature gear wear and excessive heating which will cause the main gear to fail early. While on the other hand too loose of a mesh will not give you proper engagement, which will cause excess stress to be placed on the tips of the teeth causing the gear to fail as well. When you have that perfect mesh the gear should show little signs of wear and should last many flights.

Getting that perfect gear mesh between the pinion and the main gear can be quite the challenge. However it is not something to overlook the importance of. As too tight of a gear mesh can lead to premature gear wear and excessive heating which will cause the main gear to fail early. While on the other hand too loose of a mesh will not give you proper engagement, which will cause excess stress to be placed on the tips of the teeth causing the gear to fail as well. When you have that perfect mesh the gear should show little signs of wear and should last many flights.

The main reason setting the mesh is so difficult is because there really is no reference, especially for you new guys. So we can say “just make sure there is a little bit of play” but that means almost nothing to you because what does a “little bit” mean? Hopefully through this tech tip you can understand how I set my gear mesh, which has proven successful for me.

To start this is the method I use on all of my helis. It does not matter what class they are or whether they are nitro or electric. What you want to do is loosen up the mount so that you can slide the motor forward or backward by hand, making the mesh tighter or looser. Then adjust the mesh so that the gear is partially engaged. What you want to do now is make a mental note of the amount of slop/lash in the gear. Then rotate the gear around maybe 20 degrees and check the lash again. Continue to do this as you work your way around the entire gear. The entire time be sure that you are comparing the lash to the previous positions. The goal of this is to identify the spot on the gear that is the tightest. Lets face it even the best manufactured gear is not perfectly round, all of them should have one spot that is slightly tighter than the others.

Once you have successfully identified the tightest spot go ahead and move the gear so that the tight spot is engaged with the pinion. Now what you want to do is adjust the mesh so that there is zero slop or play at that tight point. By this I don’t mean put a ton of pressure on the mesh to make it tight and induce a constant pressure on the gear, but just press them together and confirm that there is no lash. Once you have done this go ahead and tighten everything up. Now when done correctly you should be able to rotate the gear back around and there should be a slight amount of lash everywhere except at that tight spot where there is none.

That is it. This will help you achieve the tightest mesh that you can without inducing a constant and unnecessary lateral force on the gear due to a tight mesh. Please feel free to comment below or email me if you have any questions.

-Jessie