With most of the newer nitro models adjusting the clutch bell runout simply isn’t possible. Components are becoming more “plug and play” and, in turn, our habits of checking this these can get quite lax. The issue with this is that they can still have runout problems due to machining flaws. Excessive wear of clutch block bearings, fuel foaming in the fuel tank, and drifting in your flybarless system are all symptoms of a vibration issue.

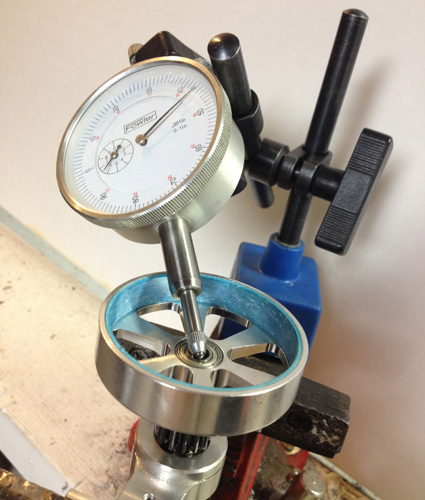

A dial indicator is a great tool to have in your arsenal and can be used to help prevent and diagnose vibration issues. No more than .001″ (one thousandth) should be present on the inner race of the starter shaft bearing. When checking this it’s also a good time to check and make sure the clutch bell itself isn’t deformed (possibly from a crash?). I have gotten in a habit of performing these checks on new components and after crashes.

– Nick